Sheet metal parts are often easily oxidized during processing, transportation, and storage, with scratches, welding slag, oil, and other contaminants. Therefore, surface treatment is very necessary. At present, there are two widely used ones: powder electrostatic spraying and electroplating.

Powder electrostatic spraying

1. Remove the dust and oil on the surface of the cold-rolled steel plate through pretreatment, and then spray the powder. The pre-treated workpiece must be completely dried and cooled to below 35 degrees, so as to ensure the quality after powder spraying.

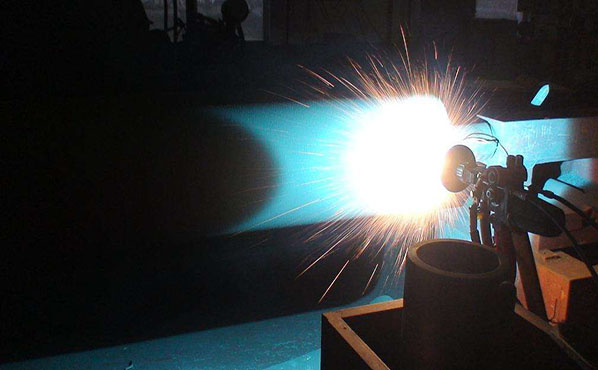

2. Sheet metal parts enter the powder spraying work. Sent to the sheet metal by an electrostatic generator, this high-voltage static electricity ionizes the mixture of powder and compressed air ejected from the nozzle of the spray gun and the air around the electrodes. The sheet metal parts are connected to the ground by conveying through the hanger, so that an electric field is formed between the spray gun and the sheet metal parts. The powder reaches the surface of the sheet metal parts under the dual action of the electric field force and the compressed air pressure, and forms on the surface of the workpiece by electrostatic attraction. An even coat.

3. Curing. The powder on the surface of the sheet metal melts after the temperature rises. After the powder melts, it begins to flow slowly, forming a thin and flat layer on the surface of the sheet metal part. After the temperature continues to rise, there is a short-term gelation state after reaching the glue point, and then the temperature continues to rise and the powder undergoes a chemical reaction and solidifies. The cured sheet metal parts should be checked for appearance, gloss, color difference, adhesion, hardness and thickness.

plating

Electroplating is a redox process. During electroplating, the metal part is used as the cathode, and the plated metal is used as the anode, which are respectively hung on the copper rods and immersed in the electrolyte solution containing the coating components, and are fed with direct current. The level that affects the electroplating process mainly includes the external environment and the internal environment. Temperature has an important influence on the quality of the electroplating surface and the efficiency of electroplating. The pH value of the plating solution must be tested frequently, and the composition of the plating solution needs to be managed, mainly through chemical analysis, and regular sampling tests according to regulations are enough. In today's era of continuous industrial development, people's requirements for product appearance are getting higher and higher. Some new surface treatment technologies have developed rapidly in recent years and have been widely used in all walks of life.

The above are the two spraying methods in sheet metal processing. If you want to know more about sheet metal processing, please pay attention to Guangzhou Platinum Shield Processing.