The application range of the sheet metal processing industry is expanding, from daily necessities to industrial electrical appliances, all involving sheet metal processing technology. Common products such as computer cases, metal switches, etc., how to control the processing quality of sheet metal cabinets?

1. Operator factors

Operators have poor quality awareness, careless operation, non-compliance with operating procedures, low operating skills, unskilled technology, and tiredness caused by simple repetitive work. Controllable measures to prevent defects include: (1) Strengthen the establishment and improvement of the quality responsibility system; ( 2) Formulate clear and detailed operating procedures, and strengthen professional process training; (3) Strengthen the "three inspections" and appropriately increase the frequency of inspections (including self-inspection); (4) Eliminate problems by adjusting personnel between job types and enriching work experience. Operator boredom, promote self-improvement, enhance self-improvement ability (cultivating versatile employees).

2. Material factors

The main control measures include: (1) clarify the quality requirements in the process of raw material procurement; (2) strengthen the inspection of incoming raw materials; (3) reasonably select suppliers; (4) improve the cooperative relationship with users to help users do a good job in quality control and quality control. Quality assurance work.

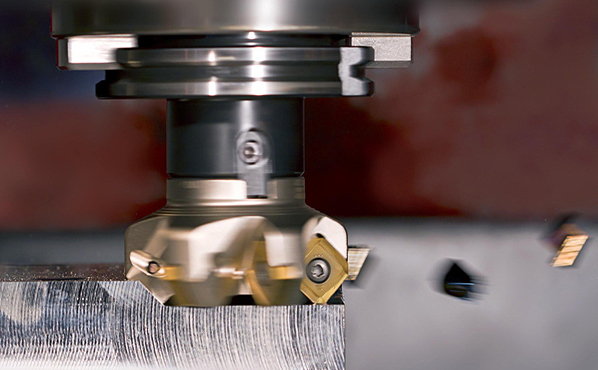

3. Mechanical factors

The main control measures include: (1) Strengthen equipment maintenance, regularly test the key accuracy and performance items of the equipment, establish a daily spot inspection system for key parts of the equipment, and control the equipment at the process quality control points; (2) Adopt the first article inspection system Verify the adjustment amount of the positioning or dosing device; (3) Use CNC machine tools as much as possible to reduce the dependence on the reliability of workers' operation; (4) Gradually establish an equipment management system to achieve good equipment performance.

4. Sheet metal processing technology

The process method includes the arrangement of the process flow, the connection between the processes, the selection of the process processing means and the preparation of the process processing guidance document. The influence of the process method on the process quality mainly comes from three aspects: first, the correctness and rationality of the process method, selected process parameters and process equipment; second, the seriousness of implementing the process method; third, supervising the inter-departmental process. implement

The process approach constitutes the technical content of the product. Reasonable process can reduce product cost and improve product qualification rate. It can be said that a reasonable process and correct production operation process constitute a qualified product.

The above is the little knowledge of sheet metal processing. Do you want to know more about sheet metal processing? Platinum Shield will continue to give you more knowledge about sheet metal processing.