All stainless steel sheet metal is a production process. Until now, sheet metal has not been perfectly defined. According to the definition of overseas publications, it can be defined as: sheet metal is a comprehensive cold drawing process of metal plate.

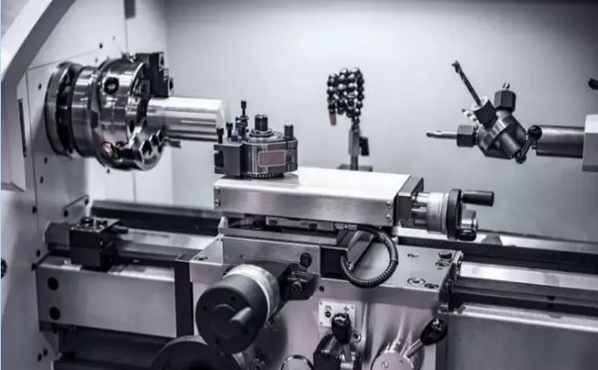

All or most of the processes of CNC sheet metal are applied to CNC machinery, such as CNC machine tools, CNC laser cutting machines, CNC cutting machines, etc. High product accuracy can be achieved and product development time can be reduced. It can go from drawing to commodity electronic production in no time. Suitable for small batch production of various intelligent production. But the leadership of some people is not a disadvantage, it is just that everyone is in a passive state, so everyone lags behind the European and American countries. We know that industrial production and manufacturing are the strengths of Germany, and product development of the facilities is certainly the strength of these people. So far, most of the facilities imported by China have been produced in Germany. CNC sheet metal machinery and equipment are also, of course, small and medium-sized we can produce by ourselves, so import does not need to be considered.

As a precise production and processing method, CNC sheet metal processing can cut almost all raw materials, including two-dimensional cutting or three-dimensional cutting of thin metal sheets. In the automobile manufacturing industry, the cutting technology of straight lines in interior spaces such as car roof windows has long been widely used. Volkswagen of Germany uses a laser generator with an output of 500W to cut complex body panels and various beveled parts. In the aerospace industry, CNC sheet metal technology is suitable for cutting titanium alloys, aluminum alloy profiles, nickel-based alloys, nickel-iron alloys, stainless steel plates, beryllium oxide, composite materials, plastics, porcelain, quartz stone and other special aviation materials. The aerospace components processed by CNC sheet metal include automobile engine flame tube, titanium alloy thin-walled chassis, airport structure, titanium alloy skin, aircraft wing truss, automobile tail panel, helicopter main rotor aircraft, spacecraft porcelain insulation tile, etc.

The key to sheet metal processing at this stage is to cut metal materials commonly used at this stage, such as stainless steel plates, iron and aluminum alloy plates, etc. Because this is a common product chemical in daily life, CNC sheet metal is not cutting any metal material. Rare metals such as precious metals are his disadvantage.