What are the effects of plastic deformation in sheet metal processing? Plastic deformation of sheet metal processing is a common process. Since the grains are connected to each other by the attraction between atoms and the mechanical interlocking force between the grains, the intergranular deformation is difficult. The slippage between grains is very small, and it is easy to cause structural damage at the grain boundaries, which leads to the fracture of the metal.

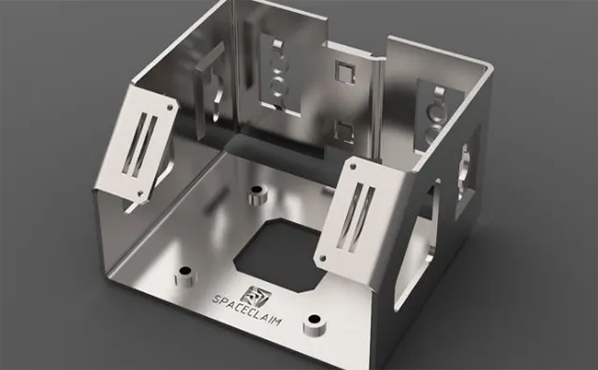

Sheet metal processing:

The rotation process between grains is quite complicated. This is because the grains of different orientations in the polycrystal both tend to rotate in the direction that is conducive to intragranular slip, and are restrained by each other. The phenomenon of grain rotation can be observed after stamping and forming of sheet metal with coarse grains, which is the so-called "orange peel" phenomenon that the surface of sheet metal parts shows unevenness.

The plastic deformation of polycrystals is also affected by grain boundaries. The lattice distortion in the grain boundary is even worse, and the existence of the grain boundary makes the strength and hardness of the polycrystal higher than that of the single crystal. The finer the grains in the polycrystal, the larger the proportion of the grain boundary area, and the higher the strength and hardness of the metal.

In addition, the finer the grains, the easier the deformation is dispersed in many grains, so the deformation is more uniform, and it is not easy to cause stress concentration to cause metal damage. better reason.

In the process of metal plastic deformation, the properties and structure of the metal will change, and the most important one is work hardening, that is, with the increase of the degree of deformation, the deformation resistance increases, the strength and hardness increase, while the plasticity and toughness decrease.

In addition, due to uneven deformation, there will be different internal stresses inside and between the grains, which remain inside the metal as residual stress after deformation, so that the cold-deformed parts may automatically deform or even deform after being placed for a period of time. cracked. The changes in properties of metals after plastic deformation are the result of changes in their microstructures.

When the polycrystal is deformed, each crystal grain is elongated in the direction of greater deformation, and when the deformation degree is large, it is significantly elongated to form a fibrous structure. Intragranular deformation will break the grains and form many small grains, that is, subgrains; intergranular deformation will break the grains at the grain boundaries, forming many small grains, that is, subgrains; intergranular deformation is in the grain boundaries. caused a lot of damage.

In addition, when the degree of deformation is large, the orientation of each grain in the polycrystal will gradually tend to be consistent due to the turning of the slip plane, forming a deformation texture. The formation of deformed texture causes anisotropy in the rolled sheet, which is generally difficult to eliminate even if annealed. The workpiece punched out of this material has uneven thickness and uneven edge, which will make the deep-drawn cup shape The mouth of the part forms a lug.