Maintenance is the first element of any mechanical equipment that needs to be used for a long time. If you do not pay attention to maintenance, no matter how good the equipment is, it will not be durable. Just like a car needs regular maintenance, the same is true for laser equipment.

1、Cooling system maintenance

Before the machine works, make sure the laser tube is filled with circulating water. The quality of the circulating water and the temperature of the water directly affect the life of the laser tube. Therefore, it is necessary to regularly replace the circulating water and clean the water tank, and the general replacement frequency is one month.

2、Dust removal system maintenance

Using the fan for a long time will cause a large amount of dust to accumulate and form solid accumulation inside, which makes the fan noisy, and is not conducive to emptying and deodorization. The fan needs to be cleaned regularly.

3、Maintenance of optical system

There will be mirrors and focusing mirrors on the machine. The laser light is reflected, focused and emitted from the laser head through these lenses. Lenses are easily covered by dust or other contaminants, resulting in loss of laser light or damage to the lens. For this reason, the lenses should be cleaned every day. Pay attention when cleaning: 1) The lens should be wiped gently to avoid damaging the surface coating; 2) The cleaning process should be gentle to avoid falling; 3) The focusing lens should be installed with the concave side facing down.

During the laser cutting process, the focusing mirror has no displacement problem, but the three mirrors are fixed by the mechanical part, and the displacement is more likely. Although displacement usually does not occur, users are advised to check that the optical path is normal before each job.

4、Transmission Maintenance

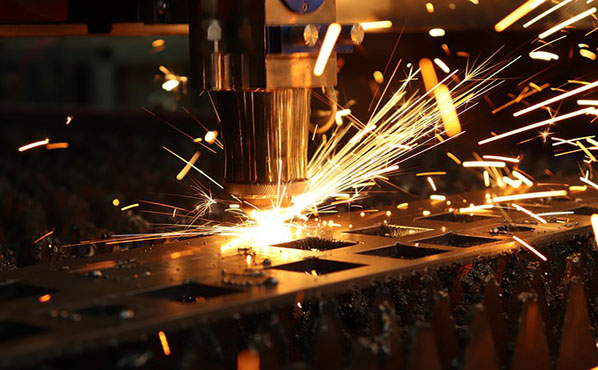

In a laser cutting machine, the transmission system is equivalent to human hands and feet. The drive system has a direct impact on the normal operation and life of the machine. The laser cutting machine will generate smoke and dust during the long-term cutting process. These fine smoke will enter the machine through the dust cover and adhere to the rack. Long-term accumulation will increase the wear of the rack. The rack guide is originally A relatively precise accessory will also cause damage to the slider and gear over time. Therefore, the rack and pinion track should be cleaned regularly. After cleaning the dust attached to the rack and pinion track, the grease and lubricating oil on the rack and pinion should be smeared on the track.

- Monthly Inspection and Maintenance

- There must be no foreign objects on the front and back of the machine to prevent it from scratching with the table.

- Clean the mirrors, check the optical path for drift, and make any necessary adjustments.

- There should be no debris in the machine guide rail, so as not to damage the guide rail seat.

- Check the shift switch bracket for loose screws.

- Clean the muffler filter of the oil-free air compressor. If the working environment is dusty, it should be cleaned once a week.

- The freeze dryer cleans the automatic drain and installs it as it is after cleaning.

6.Quarterly Inspection and Maintenance

1. Replace the oil of the laser vacuum pump.

2. For the gas inlet filter of the laser vacuum pump, see the laser manual for details. 3. It is recommended to maintain and maintain the voltage regulator once every three months. Pay attention to the maintenance work and disconnect the power supply.

Regular statistics on the use of equipment should also be carried out regularly. If there is a deviation, it should be replaced or repaired in time to prevent it from happening.

Want to learn more about sheet metal processing? Bolden will continue to give you more knowledge about sheet metal processing.