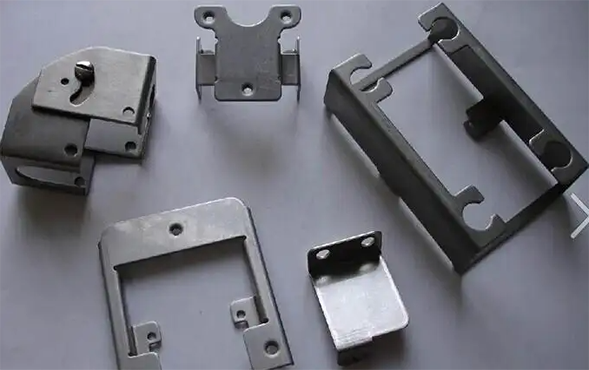

For every processed product, there must be a process, the process. Of course, sheet metal processing is no exception. What are the specific processing steps of sheet metal processing? How to process? Let's talk about the processing steps of sheet metal processing....

With the continuous update and development of production equipment, most of the forming process is completed on the machine. Manual methods are often used as auxiliary machining and finishing work. However, in the case of single-piece production or some parts with complex shapes, manual operation and machining are still essential. The manual forming of sheet metal parts is mainly done by using some simple tire shapes, profiling and various jigs. Manual forming mainly adopts the following methods: bending, standing edge, edge closing, edge pulling, arching, piping, welding joint correction, etc. The following introduces the connection method of Xiaobian 1 welded sheet metal parts. Welding refers to the process of heating the weldment locally or as a whole or causing plastic deformation of the weldment, or heating and plastic deformation at the same time to achieve permanent connection. It can be divided into manual arc welding, gas shielded welding, laser welding, segmented welding and contact welding. The main staff of our company use gas shielded welding and contact welding.

(1) Contact welding is a welding method in which the welded part is pressed to form a welded joint in the molten state or non-melted state of the connecting part during the contact welding process. It can be divided into butt welding, spot welding and seam welding.

(2) Gas shielded arc welding - During gas shielded arc welding, the electrode arc area and the welding pool are protected by shielding gas, and argon is used to protect the plum rain oxides and inclusions on the surface of the weld. Welding can be carried out in any space, the welding forming process can be observed and adjusted with the naked eye, and the production efficiency is high.

2. threaded connection

The threaded connection has the advantages of easy on-site installation, convenient disassembly, and simple operation. It is usually used for detachable structural steel connections. It can be divided into threaded connection and bolted connection.

3. riveting

Riveting is a method of joining metal structural parts or assemblies with rivets. There are many kinds of rivets. Our commonly used rivets include closed round head blind rivets, closed countersunk head blind rivets, open round head blind rivets and open countersunk head blind rivets.

4. bonding

A connection method in which the desired connection pieces are pressed together with an adhesive.