There are new developments in laser cutting all the time. Below are some typical applications of laser cutting today.

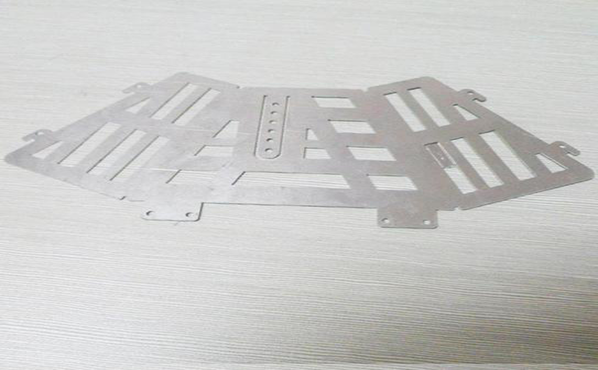

metal cutting

Laser cutting is a universal tool across industries, and is also suitable for many metals. Laser cutting can produce cleaner, smoother, tighter cuts than machining. Like machining, it can be programmed and directed by a computer, meaning laser cutters can automatically produce large numbers of metal parts for automotive, computer and other industries.

Oddly shaped items, such as car frames and hydroformed parts, often require laser cutting, as do many parts in the aerospace industry, and the results are often superior to plasma cutting.

reflective metal

Now that we've talked about metals, why are we talking about reflective metals? Because reflective metals reflect light from backlights, this is a problem when hitting them with high-powered laser beams. If the metal reflects the laser, it will self-destruct.

The solution to this problem is fiber laser cutting. In this technique, a fiber optic cable sends the laser beam onto the metal. The reflected light will not cause any damage to the fiber optic cable. Metals such as aluminum, silver, copper and gold are highly reflective and are essential in the manufacture of automobiles and semiconductors.

medical science

Laser cutting also plays an important role in the medical industry, where extreme precision and tight dimensional tolerances are required. The medical industry requires high throughput, and this technology, which can replicate designs accurately and quickly, meets those needs.

Many types of medical devices, from cardiovascular and orthopedic devices to surgical implant components, have their origins in laser cutting. Laser cutting allows these devices to be manufactured at high speeds without sacrificing precision.