Precautions for using a laser cutter.

1. Ensure the safe contact of the power socket and the safe grounding of the ground wire.

2. Ensure that the working voltage of the refrigeration compressor is stable and normal.

Because the refrigeration compressor is very sensitive to the power supply voltage, the standard product voltage for normal operation is 200-250V (110V model is 100-130V). If a wide operating voltage range is really required, it can be individually customized.

3. The mismatch of power frequency will cause damage to the machine.

Please use the 50Hz or 60Hz model according to the actual situation.

4. In order to protect the circulating pump, it is strictly forbidden to operate without water.

Make sure the tank is full of water before starting the machine. Otherwise, the water pump can be easily damaged. If the water level in the water tank is lower than the green (NORMAL) range on the water level gauge, the cooling capacity of the chiller will drop slightly, so make sure the water level in the water tank is within the green (NORMAL) range of the water level gauge. It is strictly forbidden to use the circulating pump to drain water.

- Make sure that the air inlet and outlet passages of the chiller are smooth.

The air outlet on the top of the cooler must be at least 1250px away from any obstructions, and the air inlet at the side must be at least 500px away from any obstructions.

6. The filter screen of the air inlet must be cleaned regularly.

Dust filters must be dismantled and cleaned regularly. Serious blockage of the dust filter can lead to the failure of the cooling system.

7. Beware of the effects of condensation.

If the water temperature is lower than the ambient temperature and the ambient humidity is high, condensation will form on the circulating water pipeline and the surface of the object to be cooled. If the above situation occurs, it is recommended to increase the water temperature or insulate the water pipe and the object to be cooled.

8. This product is industrial equipment and should not be operated by non-professionals.

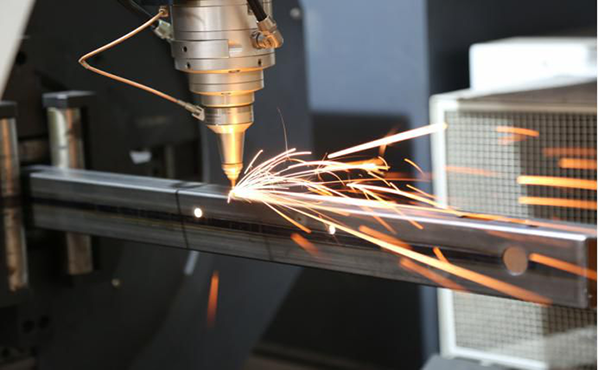

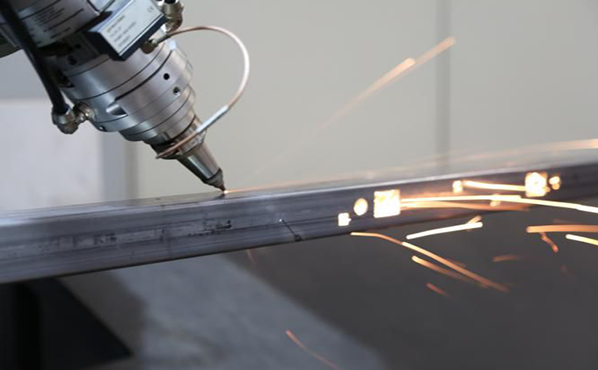

Laser cutting machine is a revolution in sheet metal processing and a "machining center" for sheet metal processing.

The laser cutting machine has the characteristics of high flexibility, fast cutting speed, high consumption efficiency, and short product consumption cycle, which has won the general favor of customers. Whether simple or complex parts can be cut with laser fine rapid prototyping. It has narrow slit, high cutting quality, high degree of automation, simple operation, low labor intensity, no pollution, automatic layout, can complete the cutting of nested materials, can improve the material application rate, low consumption cost and good economic benefits . The effective life of this technology is very long. At present, most of the fiber laser cutting machines used abroad exceed the sheet thickness of 2MM. Many foreign experts have analyzed that the next 30-40 years will be the golden period for the expansion of laser processing technology (the expansion of sheet metal processing). direction).