In order to safely process an object with a laser cutting machine, it is necessary to learn the use and maintenance skills of the equipment, so as to better exert the perfect effect of the equipment, and at the same time greatly improve the working efficiency of the equipment.

4) The guide rails should also be cleaned from time to time to eradicate dust and other debris. To ensure that the equipment is normal, the racks should also be wiped frequently. On the premise of ensuring lubrication and no debris, add some lubricating oil. The guide rails of the machine should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently, so that the machine can move better during the working process, cut more accurately, and cut out Product quality will be greatly improved.

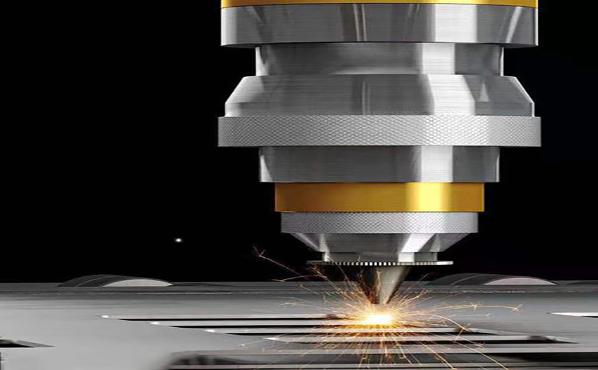

5) The dual-focus laser cutting head is the most vulnerable item on the laser cutting machine, and it is crucial for long-term operation, which will directly cause damage to the laser cutting head and also cause the shutdown of its equipment.

Laser cutting machines need more than just regular inspections and maintenance. If deformation or other forms appear, then you should know that the laser cutting head has been somewhat damaged and should be replaced. Failure to replace it will affect the cutting quality and increase the cost. Some products may also require secondary processing, reducing production efficiency. Look for the laser cutting head produced by Huagong Farley, and check carefully when purchasing to prevent problems during use.