Sheet metal processing is an important part of the metal processing industry. In recent years, my country has made great progress in the structural design and production process of chassis and cabinets, and many excellent sheet metal processing enterprises have made outstanding contributions.

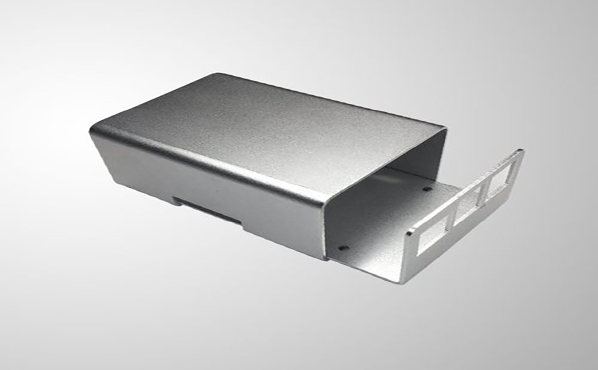

The assembly cabinet replaces the original structure. The overall welding structure of the original hot-rolled angle steel and section steel has been basically eliminated and replaced by the cold-rolled steel plate bending and cold-rolled bending assembly structure.

The combination cabinet has the advantages of flexible assembly, easy expansion, standardized design, and flexible production. Application of non-ferrous metals and their alloys Non-ferrous metals and their alloys, such as aluminum and aluminum alloys, zinc and zinc alloys, have the advantages of easy forming and high precision, and have become the latest development trend, and have been widely promoted in different fields and application. They can be used to manufacture cabinets with complex shapes and structures, as well as connectors, trim and primary support frames. With the popularity of combination cabinets, the application of non-ferrous metals and their alloys has become more and more extensive. Foreign advanced sheet metal processing technology and equipment, such as CNC shearing machines, CNC multi-station punching machines, and CNC bending machines and sheet metal processing machines have been introduced in my country. Gold flexible processing line. In particular, some enterprises have also installed pre-painting and electrostatic spraying production lines, which have played an important role in improving the performance of chassis and cabinets. The technical level and processing capacity of my country's cabinets have been greatly improved.

With the gradual improvement of advanced structural design concepts and the application of new technologies and processes, the requirements for cabinet performance are getting higher and higher. Foreign advanced ergonomic design, modular design, system design and other design methods have been popularized and applied in my country, which has greatly promoted the development of my country's chassis and cabinets

Relying on the application of electronic technology and computer technology in the electrical field, the electromagnetic shielding and electrostatic discharge protection functions of chassis and cabinets have been significantly improved. Therefore, as a carrier of electrical equipment and electrical environment, it is becoming more and more important not only as electrical equipment, but also as mechanical equipment

In the future, the upgrading of technology, equipment and concepts in the sheet metal processing industry will continue, and sheet metal enterprises will also show a polarized development trend. More and more enterprises realize that only by increasing the technical input of products and developing new products with differentiation and high-tech content can they win the initiative in market competition.