Modern stainless steel sheet metal processing decorative art design surface coloring professional skills mainly have several effects in detail, and often get unexpected effects during the practice process.

The professional skills of facial texture effect refers to the production of texture effects on the surface of stainless steel sheet metal processing through professional techniques such as forging, engraving, grinding, polishing, and dipping.

Flat polishing is a kind of factory polishing material for stainless steel sheet metal processing by applying mechanical equipment or manual production methods. After surface polishing, mirror glass, satin fabric, sandblasting and other effects. Depending on the finish, the items and methods used will vary.

Sandpaper, frosted sandpaper, magic light wheel, polishing belt, sand wheel, etc. with wear-resistant materials on the surface. During the grinding process, many wear-resistant material particles are equivalent to many very high-strength blades, which are drilled and processed on the surface of the stainless steel sheet metal factory, and then leveled.

Mirror glass effect gas polishing and fine polishing, pre-polishing is the process of applying a forced or hard polishing wheel to the surface of the polished stainless steel sheet metal factory, which can produce rough impressions on the cut surface. Craftsmanship applies flexibility to the pre-polished surface for further production processing to remove imprints left before polishing, resulting in a bright mirror glass.

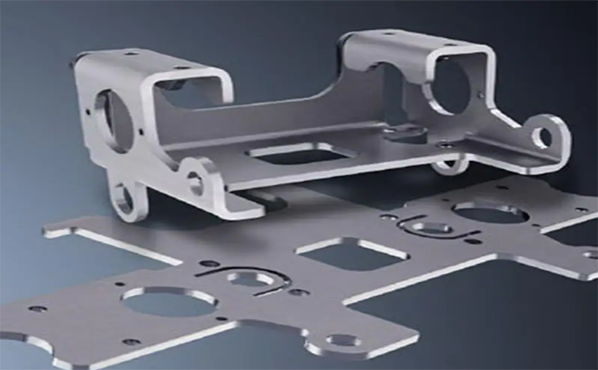

The laser cutting processing of metal materials is used in sheet metal processing plants all over the country, and its application range is so wide that it really covers all fields. If you count the professional skills of sheet metal cutting (the thickness of the metal plate is below 6 mm), it is nothing more than cutting laser cutting, low temperature plasma cutting, flame cutting, hydraulic shearing machine, stamping dies, etc. In this industrial base, laser cutting machines have been popular in the past two years and have developed rapidly. In the industry of cutting metal sheet materials, from micron-level thin plates to tens of mm thick steel plates, they can be effectively cut. To a certain extent, laser cutting machines have brought a professional skills innovation to sheet metal processing plants. In comparison, in traditional cutting, laser cutting is easier to understand and understand, and has certain advantages in the production and processing effect and speed required in the store. Therefore, it is believed that in the future cutting method selection, laser cutting Cutting will be an inevitable trend.