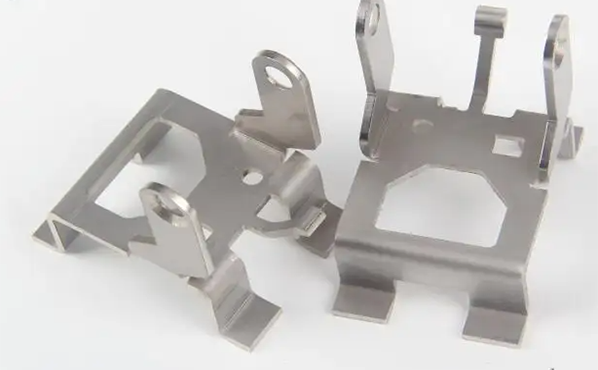

Many job industries require sheet metal fabrication. There is a lot involved in this job, including machining processes such as blanking and material bending. In these processing processes, operators should pay attention to whether the parameters are accurate and whether the use method meets the standard requirements. At present, the workplace also attaches great importance to the processing quality of materials, therefore, during this processing operation, we should also pay attention to the application of technical skills and knowledge to meet the needs of industry development.

When processing sheet metal materials, care should be taken to minimize energy consumption. Although for operational tasks, reducing material input has little impact on cost recovery. For a large number of long-term processing, if the main purpose is to shorten the input and loss, more expenses can be reduced and more economic benefits can be brought to the manufacturer.

1. The thickness and quality of the metal plate should meet the standards, and the materials used should have a clear performance test report and factory certificate. The appearance of the material should be smooth and free of rust, cracks and deformation. According to drawings or technical requirements, if there is no fixed standard, it needs to follow the national standard.

2 execute. The whole batch of plastic powder should have good consistency, and provide clear factory certificate and inspection report, powder number, color number and various inspection parameters. Pass the test.

3 Determine whether the plastic powder meets the performance requirements for color, gloss, leveling and adhesion. The appearance of general hardware and fasteners is free of rust and burrs, and the appearance of the whole batch is consistent. The dimensions should conform to the machining drawings or national standards, and the trial assembly and performance should meet the product requirements.

Guangzhou Baidun Technology Co., Ltd. has been focusing on sheet metal processing for 13 years, specializing in sheet metal processing and electrical assembly, from product design, prototype manufacturing to mass production to meet customer needs.