Causes and solutions of indentation in sheet metal bending

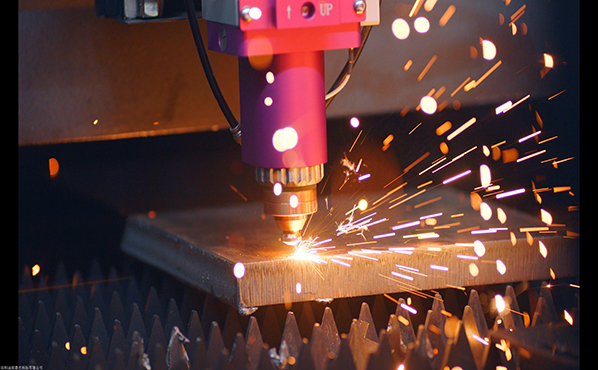

Sheet metal processing technology continues to improve, especially in some applications such as precision stainless steel bending, stainless steel decorative parts bending, aluminum alloy bending, aircraft parts bending, copper plate bending, etc. In addition, the surface quality of the workpiece has also been improved. high demands. The traditional bending process is more likely to cause damage to the surface of the workpiece, and the surface in contact with the mold will form obvious dents or scratches, which will affect the aesthetics of the final product and reduce the user's judgment on the value of the product.