Sheet metal bending is the process of changing the angle of a sheet. For example, the sheet is formed into a V shape, a U shape, or the like. Generally speaking, there are two methods of bending sheets: one is die bending, which is used for sheet structures with complex structures, small volumes and large-volume processing; the other is bending with a bending machine, which is used for structural Processing of large or small plates. These two bending methods have their own principles, characteristics and applicability.

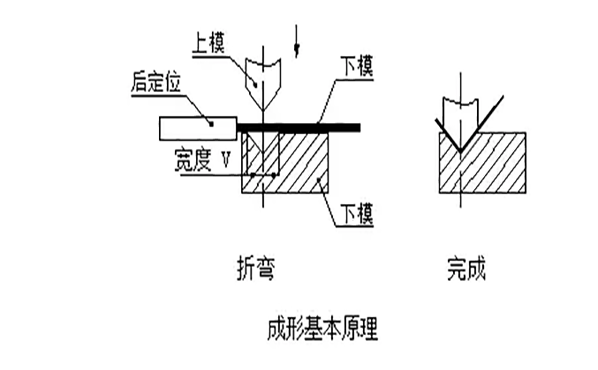

Basic principles of sheet metal bending

Basic principles of sheet metal bending...

Bending knife (upper die)

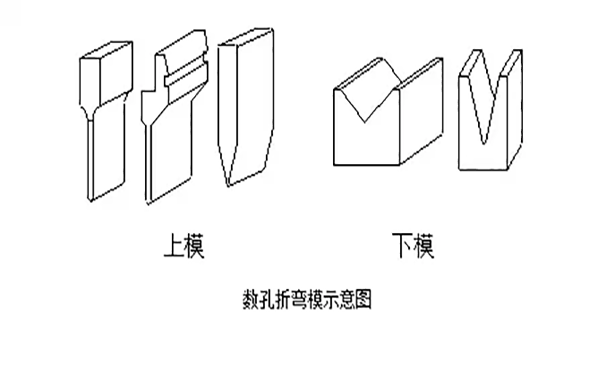

The shape of the bending tool is shown in the figure below, and the processing is mainly carried out according to the shape of the workpiece. Generally speaking, machining manufacturers have various shapes of bending tools, especially for those manufacturers with a high degree of professionalism, many shapes and sizes of bending tools are customized for processing various complex elbows .

General diewidth=material thickness6times

In order to meet the product requirements and ensure the safe use of the bending machine, the manufacturer has a series of bending dies. During the structural design process, we must have a general understanding of the existing bending dies. See the picture below, the upper die on the left and the lower die on the right.

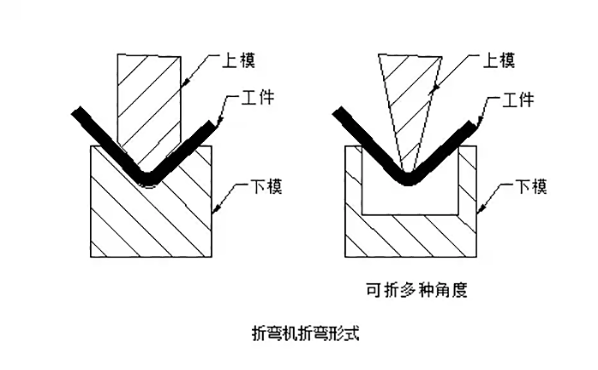

The bending form is generally as shown in the following figure:

sheet metal bendingfastcalculation method

When sheet metal is bent, one part of the material is elongated and another part is compressed, which is affected by the following factors: the type of material, the thickness of the material, the heat treatment of the material and the angle of the bending process.

- The outer layer of the sheet is subjected to tensile stress during the bending process, and the inner layer is subjected to compressive stress between the transient layers that are neither tensile nor compressive. The transient layer is called the neutral layer; the length of the neutral layer during the bending process is the same as It is the same before bending and remains unchanged, so the neutral layer is the reference point for calculating the unfolded length of the bent part.

- The basic formula of unfolding calculation: unfolding length = inside material + inside material + compensation amount

The above are the common problems encountered by sheet metal parts in sheet metal bending. Do you still want to learn more about sheet metal processing? Platinum Shield will continue to give you more knowledge about sheet metal processing.