In Guangzhou platinum shield sheet metal processing, material is the basis and one of the costs, so we must pay attention to it when calculating to avoid waste.

The processing methods of sheet metal processing include blanking, bending, drawing, forming and welding. Due to different processing methods, blanking can be divided into ordinary punching, digital punching, shearing machine cutting, laser cutting and wind cutting. Due to different processing methods, the processing technology of blanking is also different. The punching method of sheet metal is basically digital punching and laser cutting. The advantages of laser cutting are that the thickness of the sheet is large, the shape of the workpiece is cut efficiently, and the processing is intelligent. The disadvantage is that it cannot be processed and formed, the mesh parts cannot be processed in this way, and the processing cost is high. The welding methods mainly include arc welding, electroslag welding, gas welding, plasma arc welding, fusion welding, pressure welding and brazing. The welding of sheet metal products mainly includes arc welding and gas welding. Arc welding is flexible, flexible, and versatile, and can be welded in all positions; all equipment is simple, durable, and low-maintenance. The disadvantage is that the labor intensity is high and the quality is not stable enough, which depends on the level of the operator. Since the arc welding heat source is wider than the heat affected zone, the heat is not as concentrated as the arc, and the productivity is low, so the temperature and performance of the gas welding flame can be adjusted. Therefore, in the process of sheet metal processing, different process requirements must be paid attention to according to the needs of the processing method.

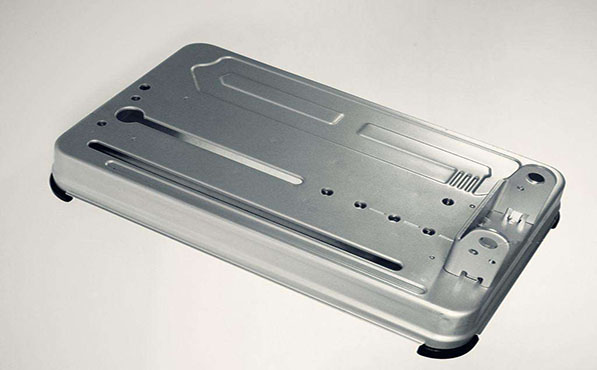

In order to meet the processing requirements, the equipment must meet certain requirements. Large-scale laser cutting machines can cut carbon steel, stainless steel and other materials, and can also use laser cutting for cutting. The section of the workpiece after processing is neat, smooth, beautiful and accurate. For the sheet metal processing process, according to the different materials of the product, the product processing degree of the materials used should also be considered. The sheet metal parts of the punch press are used for mass production, and the drawn expansion numbers are used for process cutting, generally used for sheet thickness cutting, and then used for product production. Laser technology can play a certain role in sheet metal processing.

CNC technology is widely used in sheet metal machine tools. It solves the problems of high precision, complex shape and large batch in sheet metal processing. With the wide application of sheet metal processing products in aerospace, railway transportation, environmental protection equipment, air conditioning appliances, tobacco machinery, packaging and printing, construction machinery, textile machinery, household and many other industries. Sheet metal processing not only requires more high-tech workers to operate, but also requires good equipment and excellent employees to produce good products.