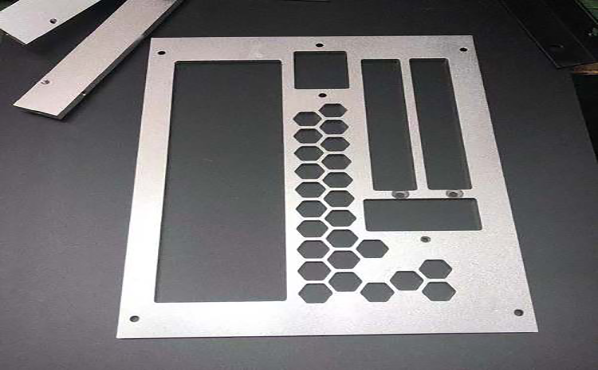

Aluminum plate used to be a difficult problem for our laser cutting, because aluminum plate is a high-resistance material, and the absorption rate of laser is very low. It is difficult to laser cut aluminum plate because its processing demand is relatively large, and we also need to consider the fast and safe laser cutting of aluminum plate. use. Let's make it our must. Copper, aluminum and other highly elastic materials can be cut and processed with laser equipment.

In the first few days of laser cutting aluminum plates, some methods can be used to reduce the difficulty of cutting, such as painting the surface of the aluminum plate black, allowing wine to reduce the degree of reflection of the aluminum plate, and then cutting. At the same time, another reason for the difficulty in cutting aluminum plates is that the parameters of the laser machine are not adjusted well. In contrast, the cutting process is usually more difficult to grasp the metal material, the incision is rough, and it is easy to hang slag.

In fact, there are many other highly reflective materials such as aluminum. This is because laser equipment is indeed sensitive to retroreflection, which can lead to unstable behavior and breakage of the laser lens during processing, requiring the use of high-power lasers and greatly shortening the life of the laser. So, do we really need a laser machine? No, of course not. In the process of processing aluminum plates, pay attention to some situations. Aluminum is not resistant to high temperature, and burrs are easy to occur when cutting. It should not be too fast during processing. At the same time, pay attention to the speed. It is easy to produce burrs when cutting. The cutting speed is too slow and it is close to the cutting opening. It may cause cracks to appear and also affect the quality of the cut.

In addition, when laser cutting aluminum plate, due to the special color of aluminum, it is recommended to use nitrogen gas to protect the uniform color of the cut product. Nitrogen can well prevent oxidation and retain the characteristics of the material itself. Nitrogen is a better choice. The cutting thickness is 2000, cutting 6-8, can be less than 4000 cutting 12, 6000 cutting 16, choose fiber laser cutting machine is more suitable for cutting aluminum plate, its wavelength absorption is better at 1064nm.