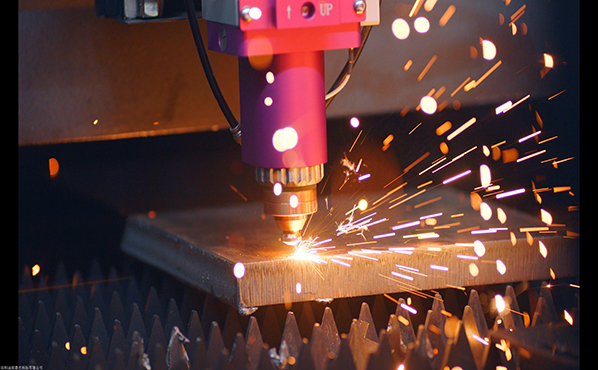

What is the cost of laser processing?

The processing cost of laser cutting machines varies. For users and consumers, how much is the appropriate laser cutting cost? There are different processing algorithms for different materials and industries. In the sheet metal industry, it is basically calculated according to the number of punches and the number of meters, and different sheets have different prices. Different thicknesses of the same material also have different prices, mainly depending on the difficulty of processing and labor time.