What is the effect of plastic deformation in sheet metal processing?

小梁

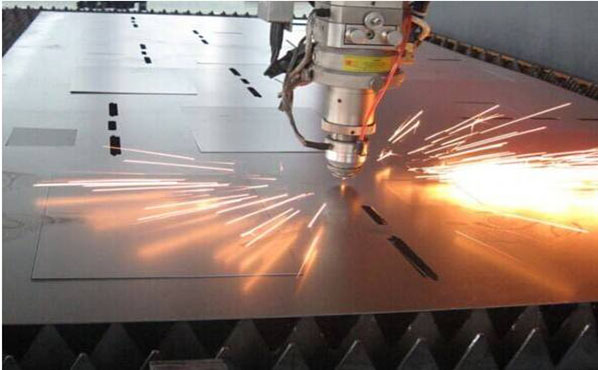

What are the effects of plastic deformation in sheet metal processing? Plastic deformation of sheet metal processing is a common process. Since the grains are connected to each other by the attraction between atoms and the mechanical interlocking force between the grains, the intergranular deformation is difficult. The slippage between grains is very small, and it is easy to cause structural damage at the grain boundaries, which leads to the fracture of the metal.