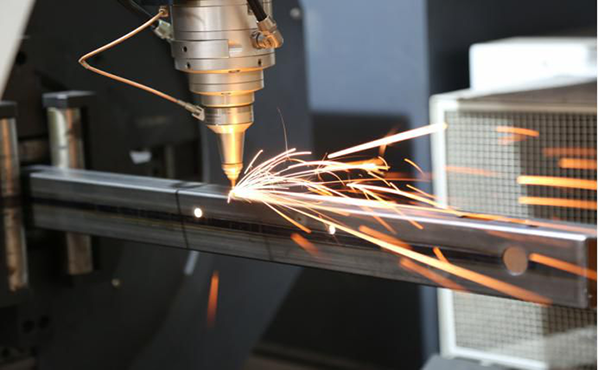

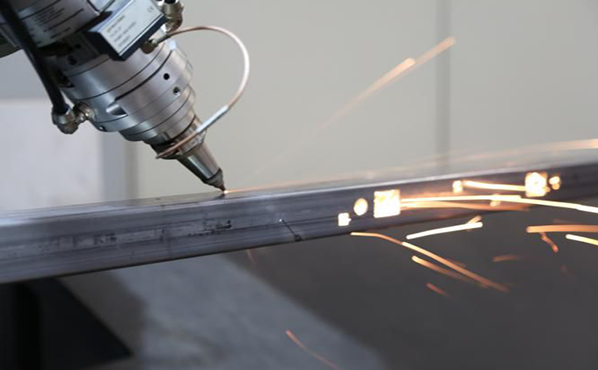

With the increasing number of people competing at present, the profit of sheet metal cutting has gradually been compressed, and price competition has not only become the norm of market development in the new era, but many merchants have begun to switch to laser pipe cutting machines. Last year, my country's foreign trade exports surged, and at the same time, it drove the development of many industries such as fitness equipment, steel and wood furniture, kitchenware and bathrooms, etc. The increase in orders has made the application space of laser pipe cutting machines larger; with the Made in China 2025 The promotion of laser pipe cutting machine technology is also facing changes and opportunities. Under the existing background, the laser pipe cutting machine has been transformed and upgraded on the original technology. The development of industrial technology has allowed laser cutting to be applied to all walks of life. Mechanization and automation will be the main theme of enterprise development in the future.