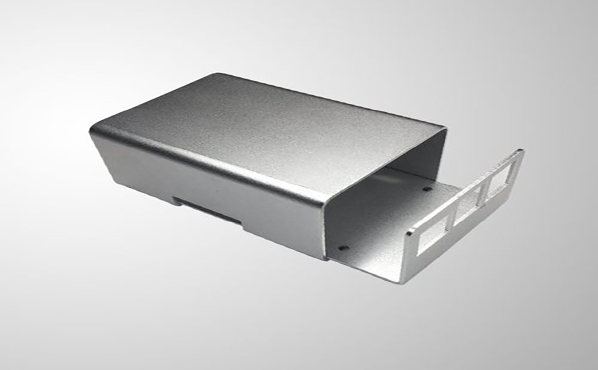

What are the commonly used materials in sheet metal processing? How to accept?

What are the commonly used materials for sheet metal processing? Commonly used materials for sheet metal processing parts are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU) brass, red copper, beryllium copper, aluminum sheet (6061, 5052, 1010 , 1060, 6063, hard aluminum, etc.), aluminum profiles, stainless steel (mirror, brushed, matte). *Different materials usually need to consider the purpose and cost of the product.