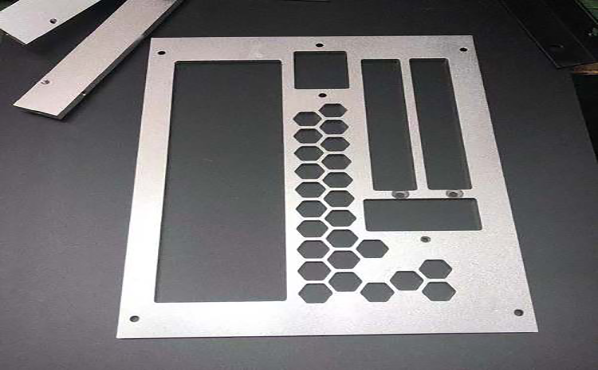

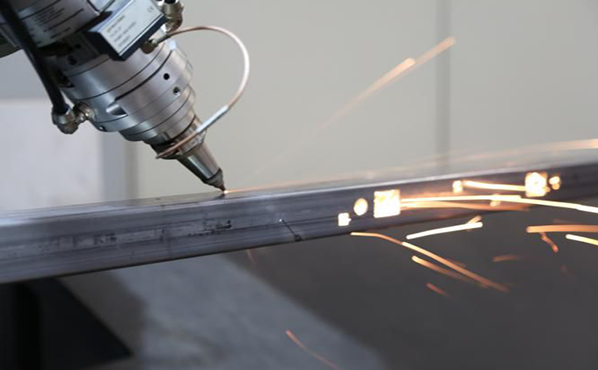

Laser cutting machine for aluminum plate

Aluminum plate used to be a difficult problem for our laser cutting, because aluminum plate is a high-resistance material, and the absorption rate of laser is very low. It is difficult to laser cut aluminum plate because its processing demand is relatively large, and we also need to consider the fast and safe laser cutting of aluminum plate. use. Let's make it our must. Copper, aluminum and other highly elastic materials can be cut and processed with laser equipment.